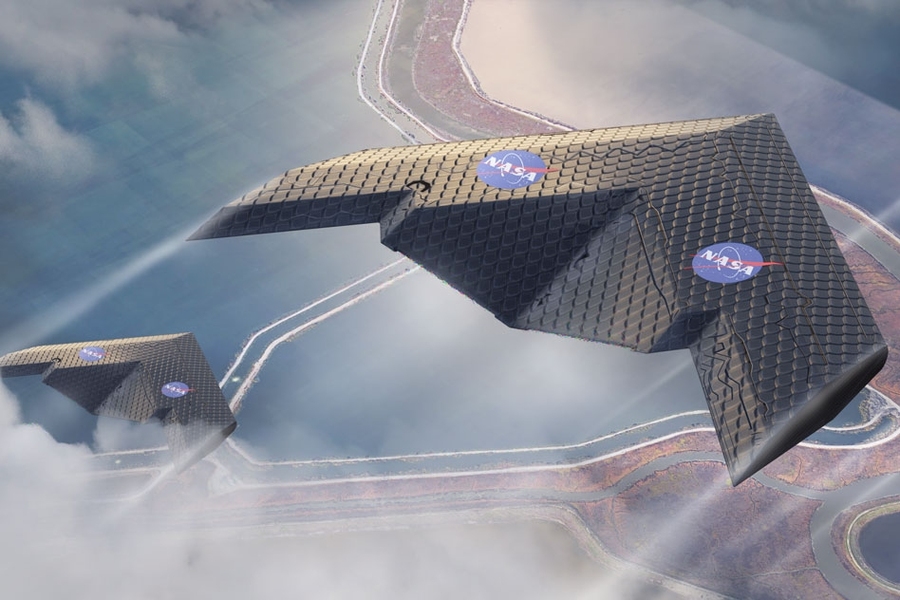

While this version was hand-assembled by a team of graduate students, the repetitive process is designed to be easily accomplished by a swarm of small, simple autonomous assembly robots. The new version, about five times as long, is comparable in size to the wing of a real single-seater plane and could be easy to manufacture. This is all accomplished by the careful design of the relative positions of struts with different amounts of flexibility or stiffness, designed so that the wing, or sections of it, bend in specific ways in response to particular kinds of stresses.Ĭheung and others demonstrated the basic underlying principle a few years ago, producing a wing about a meter long, comparable to the size of typical remote-controlled model aircraft. “We’re able to produce the exact same behavior you would do actively, but we did it passively.” “We’re able to gain efficiency by matching the shape to the loads at different angles of attack,” says Cramer, the paper’s lead author. While it would be possible to include motors and cables to produce the forces needed to deform the wings, the team has taken this a step further and designed a system that automatically responds to changes in its aerodynamic loading conditions by shifting its shape - a sort of self-adjusting, passive wing-reconfiguration process. A wing that is constantly deformable could provide a much better approximation of the best configuration for each stage. Jenett explains that for each of the phases of a flight - takeoff and landing, cruising, maneuvering and so on - each has its own, different set of optimal wing parameters, so a conventional wing is necessarily a compromise that is not optimized for any of these, and therefore sacrifices efficiency. Because the structure, comprising thousands of tiny triangles of matchstick-like struts, is composed mostly of empty space, it forms a mechanical “metamaterial” that combines the structural stiffness of a rubber-like polymer and the extreme lightness and low density of an aerogel. The result is a wing that is much lighter, and thus much more energy efficient, than those with conventional designs, whether made from metal or composites, the researchers say. The tiny subassemblies, which are bolted together to form an open, lightweight lattice framework, are then covered with a thin layer of similar polymer material as the framework.

Instead of requiring separate movable surfaces such as ailerons to control the roll and pitch of the plane, as conventional wings do, the new assembly system makes it possible to deform the whole wing, or parts of it, by incorporating a mix of stiff and flexible components in its structure. The new wing design was tested in a NASA wind tunnel and is described today in a paper in the journal Smart Materials and Structures, co-authored by research engineer Nicholas Cramer at NASA Ames in California MIT alumnus Kenneth Cheung SM ’07 PhD ’12, now at NASA Ames Benjamin Jenett, a graduate student in MIT’s Center for Bits and Atoms and eight others. The new approach to wing construction could afford greater flexibility in the design and manufacturing of future aircraft. The wing can change shape to control the plane’s flight, and could provide a significant boost in aircraft production, flight, and maintenance efficiency, the researchers say. Maximum section lift coefficients greater than 2.0 were obtained and section lift-drag ratio at a lift coefficient of 1.0 (climb condition) varied from about 65 to 85 as the Reynolds number increased from about 2.0 million to 6.0 million.A team of engineers has built and tested a radically new kind of airplane wing, assembled from hundreds of tiny identical pieces. Reynolds numbers based on airfoil chord varied from 2.0 million to 20.0 million.

The tests were conducted over a Mach number range from 0.10 to 0.28. The results were compared with predictions based on a theoretical method for calculating the viscous flow about the airfoil. Wind-tunnel tests have been conducted to determine the low-speed two-dimensional aerodynamic characteristics of a 17-percent-thick airfoil designed for general aviation applications (GA(W)-1).

It is provided to our users as a useful reference source. This document has not been validated by ESDU.

0 kommentar(er)

0 kommentar(er)